And: What has sustainability reporting got to do with layout optimization in factory planning?

In a time where sustainability and climate change mitigation are getting more and more important, companies are faced with new regulatory challenges. The Corporate Sustainability Reporting Directive (CSRD), European Sustainability Reporting Standards (ESRS) and Energy Efficiency Act (EnEFG) require companies to think over their reporting and business practices basically. This article provides a comprehensive overview of these new requirements and their impacts on the companies.

The requirements of the CSRD: The new era of sustainability reporting

The requirements of the CSRD face the companies with new challenges in sustainability reporting. This EU Directive that was adopted in November 2022 significantly expands the group of companies liable to report and requires detailed disclosure of environmental, social and governance (ESG) considerations in accordance with the following time schedule for implementation:

| Phase | Timescale | Companies concerned | First reporting |

| Phase 1 | As of January 1, 2024 | Large companies with > 500 employees – already liable to NFRD reporting | 2025 |

| Phase 2 | As of January 1, 2025 | Large companies > 250 employees, sales turnover > EUR 40 MM or total assets > EUR 20 MM | 2026 |

| Phase 3 | As of January 1, 2026 | Small and medium-sized enterprises listed on the stock exchange | 2027 |

| Phase 4 | As of January 1, 2028 | Non-EU companies performing important EU activities | 2029 |

The companies will have to rework their reporting processes to be able to meet the CSRD requirements. The Directive introduces the principle of “double materiality” taking into account both the impacts of an enterprise on the environment and society and the impacts of the aspects of sustainability on the enterprise. In addition, a mandatory verification of the information on sustainability will be introduced to increase the authenticity and comparability of the reports.

The ESRS standards: Standardization for more comparability

The European Sustainability Reporting Standards (ESRS) make the CSRD requirements for the companies in the EU more precise and provide detailed specifications for the reporting. Thanks to these new regulations, sustainability reporting is gaining more and more importance for enterprises of all sizes.

The ESRS standards were updated in April 2024, with increased focus on risk evaluation and clarification regarding climate change mitigation. The companies will have to adapt their sustainability reporting to the ESRS standards which requires comprehensive revision of the existing reporting processes.

One of the main tasks is to specify the duties of disclosure for the financial impacts of the aspects of sustainability more precisely. This requires close cooperation between the sustainability and finance departments in the companies to be able to guarantee holistic reporting.

Compliance with the Energy Efficiency Act (EnEFG): Energy efficiency as an obligation

With introduction of sustainability reporting, the Energy Efficiency Act (EnEFG) complements the CSRD and ESRS by creating national regulations for transposition of the European standards. It specifies which companies are obliged to report on sustainability and which information they must provide. The Energy Efficiency Act (EnEFG) promotes integration of sustainability objectives into the company strategy and supports the companies in documenting their progress with reference to social and ecological responsibility. The following limitations are to be taken into account for the companies:

| Max. daily consumption | Obligations | Transposition period |

| .5 GWh/year | Introduction of an energy management system / environmental management system (EnMS/UMS) in accordance with ISO 50001 or EMAS | July 18, 2025 |

| 2.5 GWh/year | Plans for transposition of energy saving measures | Up to 2026 |

Companies subject to the requirements of the Energy Efficiency Act (EnEFG) must ensure that 90% of the total final energy consumption are covered by energy management systems. In addition, there is an obligation for the companies to report waste heat potentials and to update the plans for transposition annually.

Non-compliance with the EnEfG regulations can result in severe sanctions, including, but not limited to fines up to EUR 100,000. In addition, the companies are obliged to publish their action plans and to pass regular checks by the competent authorities.

Recommended actions for the companies

In view of the complex requirements by the CSRD, ESRS and EnEFG, companies should act proactively to be able to ensure their compliance and to make use of potential competitive advantages. Here are a few concrete recommendations:

- Conduct a thorough analysis to determine whether or not you individually are subject to the new regulations.

- Check your current reporting practice and identify gaps with reference to the new requirements.

- Start with acquiring the relevant data, notably in the fields of energy consumption and sustainability performance.

The EnEfG is closely associated with the existing Act on Energy Services and Other Energy Efficiency Measures (EDL-G) whereby the EnEfG complements the EDL-G and even tightens it in a few areas. Whereas in the case of the EDL-G the focus lies rather on auditing, the objective of the EnEfG is additionally performing energy efficiency measures. The energy audit is the interface between the set of the aforementioned regulations. DIN EN 16247 specifies the quality standards for energy audits and ensures their comparability. It defines general requirements, evaluation methods and analysis procedures for energy flows.

Energy audit in accordance with DIN EN 16247

Performing an audit includes the definition of the range of application, data acquisition, detailed analysis, and elaboration of a report that comprises specific suggestions for optimization. Energy audits also take into account building layout aspects. This includes the following areas, for example:

Equipment and machinery layout:

The equipment and machinery layout plays an important part whenever the use of transport energy, such as electricity, diesel and gas, is to be avoided. In this context, in particular DIN EN 16796-1:2017-01 is important which deals with the energy efficiency of industrial trucks. But this similarly also pertains to the utilization of waste heat produced by the equipment and machinery to be able to avoid thermal losses particularly in the case of energy-intensive processes.

Illumination:

Lighting layout, use of daylight, and selection of appropriate energy illumination systems.

Indoor climate:

Layout of heating, ventilation and air conditioning (HVAC) systems, insulation of rooms, and use of passive cooling.

Which saving effects can be achieved by optimizing the layout?

The optimization of work sequences can result in reduction of the energy consumption of the equipment and machinery and in significant reduction of the transport efforts and the required energy.

Optimized layout of the lighting, HVAC systems and machines can provide considerable energy savings. Optimization of daylight utilization can reduce the need of artificial lighting.

Efficient room layout and insulation can reduce the energy consumption for heating and cooling.

For example, the knowledge gained from energy audits and the requirements of the EDL-G can be taken into account in the building layout planning in the case of construction and reconstruction to be able to guarantee high energy efficiency from the very beginning.

Energy audits provide practical support

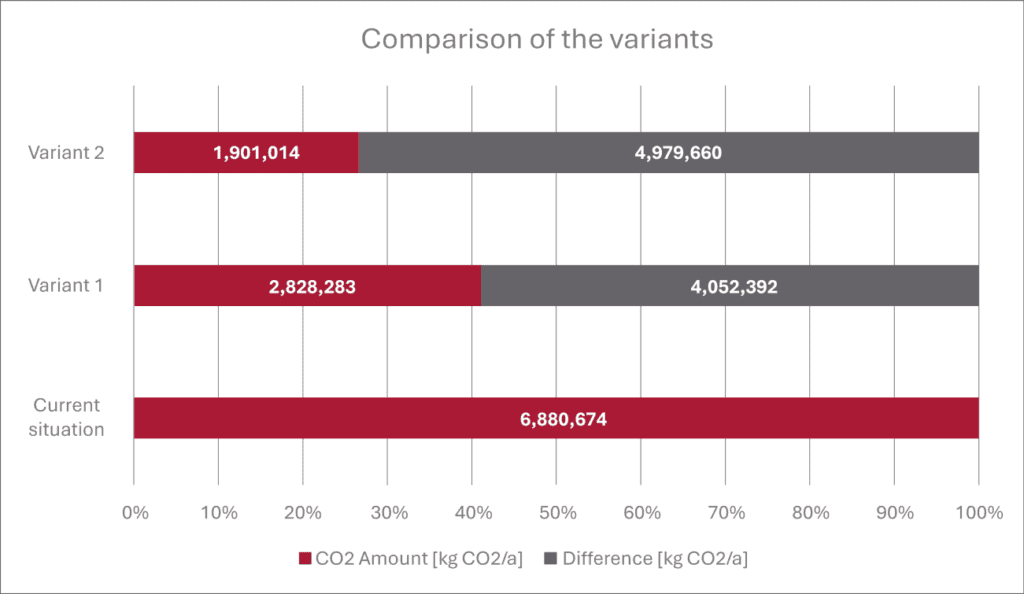

Hörmann Rawema Engineering und Consulting GmbH, for example, uses the innovative visTABLE® software to conduct energy audits in order to efficiently visualize and optimize energy consumptions arising from transports. The planning results gained from visTABLE® are also used to determine the carbon dioxide equivalents – equivalents from various processes and logistics operations. Thus, the resulting savings can be calculated precisely with the use of further tools and represented transparently by comparing different variants.

In addition, visTABLE® allows detailed analysis of the transport processes by acquiring relevant data and representing it in vivid graphics. Inefficient sequences can be identified to develop targeted measures for reduction of the energy consumption. visTABLE® gives companies valuable insights into their transport energy costs and allows them to implement sustainable strategies to increase their efficiency. This contributes not only to cost reduction, but also supports the implementation of environment objectives and sustainable company management.

No problem, simply subscribe to our Blog-News!