Value Stream Mapping Software

- Value Stream Analysis

- Identify Waste and Flow

- Value Stream Design

- Lean Management

- Value Stream Mapping

- Optimize Manufacturing

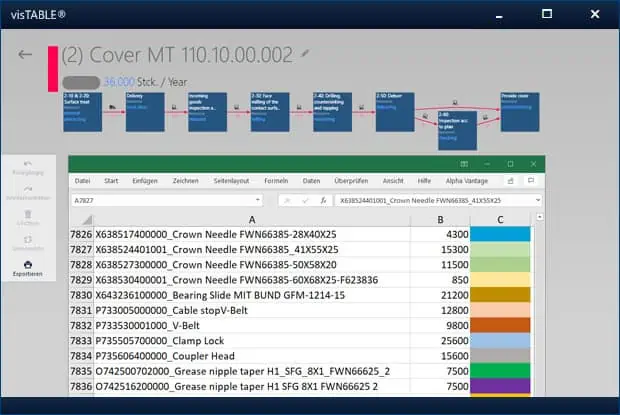

By using visTABLE® software, you can visualize the entire process. In manufacturing, value stream mapping helps identify waste by analyzing each step of material handling. The software allows to map the current state, apply lean principles to define the future state and to reduce the effort spent on non-value-adding processes. Improvement backed by VSM has never been easier.